Find the Automation That Actually Matters: How AI-Powered Process Mining Exposes High-Value Opportunities

Picture your operations team huddled around a spreadsheet that tries—and fails—to describe what really happens when work flows through your systems. A ticket moves, a field rep clocks work on their phone, an invoice sits in limbo because two systems disagree. Leaders point at charts and ask for timelines, and people on the ground mutter about exceptions, rework, and hours lost to “process work” that never seems to disappear. That feeling—frustration, fatigue, the nagging sense that you’re automating the wrong things—is exactly why AI-powered process mining matters.

Process mining turns the noise of your enterprise systems into a clear map of how work actually happens. When you pair it with AI, you stop guessing and start surfacing the processes that will deliver measurable productivity gains with the least deployment friction. Here’s how to make that shift practical, defensible, and fast.

What AI-powered process mining does, in plain terms

- It reads event logs already emitted by your systems—CRM, ERP, ticketing, mobile apps—and reconstructs the end-to-end journeys that individual “cases” take.

- It exposes where work queues up, where rework loops occur, which handoffs add the most delay, and how many different variants of the same process are actually in use.

- AI adds the ability to cluster and prioritize: unsupervised learning groups common process variants, and scoring models estimate which automations would yield the biggest time savings versus implementation cost.

Data sources to extract (and the minimum fields you need)

Start with the logs you already have. For each system, export event-level rows containing:

- Case ID (the business object: order number, ticket ID, invoice number)

- Timestamp (event time)

- Activity or event name (status changed, task completed, approval granted)

- Resource (user, role, or system that performed the activity)

- Relevant attributes (amount, product line, geography, channel)

If you can’t find a clean Case ID, create one by combining fields (customer ID + order date + sequence) or instrument the systems to start tracking it. Data alignment—consistent timestamps, standardized activity names, and reconciled user IDs—is the most common upfront hurdle.

Key metrics to watch and why they matter

Use these metrics to turn visualizations into decisions:

- Throughput time: How long does a case take from start to finish? This shows the real customer or business impact.

- Active vs. idle time: Where does work sit waiting? Idle time indicates handoffs, batching, or missing triggers.

- Rework rate and loops: Which activities commonly revert or repeat? Rework is a multiplier on effort and a prime automation target.

- Variant frequency: How many distinct ways does the process run? High variant counts often hide simple, high-volume paths suited for automation.

- Error and exception rates: Tasks that frequently throw exceptions are good candidates for AI/ML augmentation rather than pure RPA.

How unsupervised learning helps you find the right candidates

When you mine logs, you’ll often discover hundreds of variants for a single process. AI’s role is to make sense of that diversity:

- Sequence clustering groups cases by the pattern of activities they pass through, revealing the dominant “happy path” and the many detours that add cost.

- Dimensionality reduction and clustering can surface the attributes that most distinguish fast cases from slow ones—customer type, channel, or product.

- These clusters let you prioritize: automate the high-volume, low-complexity cluster first; for medium-complexity clusters, consider low-code automations; for clusters defined by nuanced exceptions, investigate ML for prediction or classification.

Prioritizing automation by ROI and complexity

A simple, defensible prioritization model uses four lenses:

- Volume: How many cases follow this path per week/month?

- Time savings per case: How much staff time is consumed on the path you intend to automate?

- Automation feasibility: Can rules and structured data solve it (good for RPA) or does it need a model to predict/triage (ML)?

- Implementation complexity: How many systems, integrations, and exception types are involved?

Score each candidate on these axes and produce a phased backlog: quick wins (high volume, low complexity), medium effort (moderate volume, some exceptions), and advanced automation (low volume or high complexity but strategic).

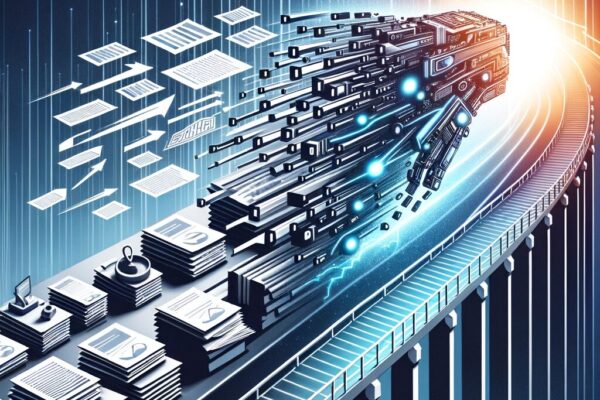

Turning insights into a phased automation roadmap

- Phase 0 — Discovery & Kaizen: Use process mining to baseline performance and align stakeholders with visual, case-level traces.

- Phase 1 — Automate the happy path: Deploy RPA or low-code flows to handle the most frequent, rule-based sequences. Measure cycle-time reduction and error elimination.

- Phase 2 — Extend with low-code integrations: Tackle mid-complexity paths where business rules need orchestration across systems.

- Phase 3 — Add predictive intelligence: Train ML models to route exceptions, predict SLA breaches, or classify documents so bots handle the rest automatically.

- Phase 4 — Continuous improvement: Re-run process mining regularly to detect drift, new variants, and automation friction.

Common pitfalls—and how to avoid them

- Bad data, bad results. If timestamps or case IDs are inconsistent, your maps lie. Invest time in data wrangling and incremental instrumentation rather than skipping this step.

- Stakeholder misalignment. Operations, IT, and front-line teams must agree on what “done” looks like. Use case traces to foster alignment—there’s less arguing when everyone can see the same evidence.

- Chasing a single metric. Cutting cycle time can increase errors if you don’t monitor quality and customer impact. Always pair speed metrics with error rates, customer feedback, or rework counts.

- Over-automation. Automating an exception-heavy path can create more work. Use AI to triage and reserve full automation for predictable, rule-based processes.

Simple before/after examples (conceptual)

- Invoice handling: Before—finance staff manually reconcile invoices across systems, pausing work for missing purchase orders and chasing approvals. After—process mining shows most invoices follow a predictable match-and-approve path; an RPA bot handles the match-and-post steps, low-code forms streamline approvals, and staff handle exceptions. Result: fewer manual touches and faster fund flows; staff shift to resolving complex supplier questions.

- Customer support triage: Before—tickets route inconsistently, creating long waits and duplicate assignments. After—clustering shows common ticket paths by channel and issue. A combination of rule-based routing and an ML classifier auto-triages routine requests, reducing handoffs and letting agents focus on escalations and retention tasks.

Why this matters to small and mid-sized businesses

You don’t need enterprise-scale budgets to benefit. Process mining uses artifacts you already produce. The right AI adds prioritization and prediction—so you don’t spend months automating low-impact work. For operations leaders, transformation managers, and technical leads, the outcome is simple: clearer choices, faster wins, and measurable time reclaimed for higher-value work.

If you want help turning your event logs into an actionable automation roadmap, MyMobileLyfe can guide the way. They combine AI, automation, and data expertise to map your real processes, prioritize opportunities, and deliver phased automation that reduces work, improves throughput, and saves money. Learn more at https://www.mymobilelyfe.com/artificial-intelligence-ai-services/.

Recent Comments