From Inbox to Issued PO in Hours: Streamlining Procurement with AI and Automation

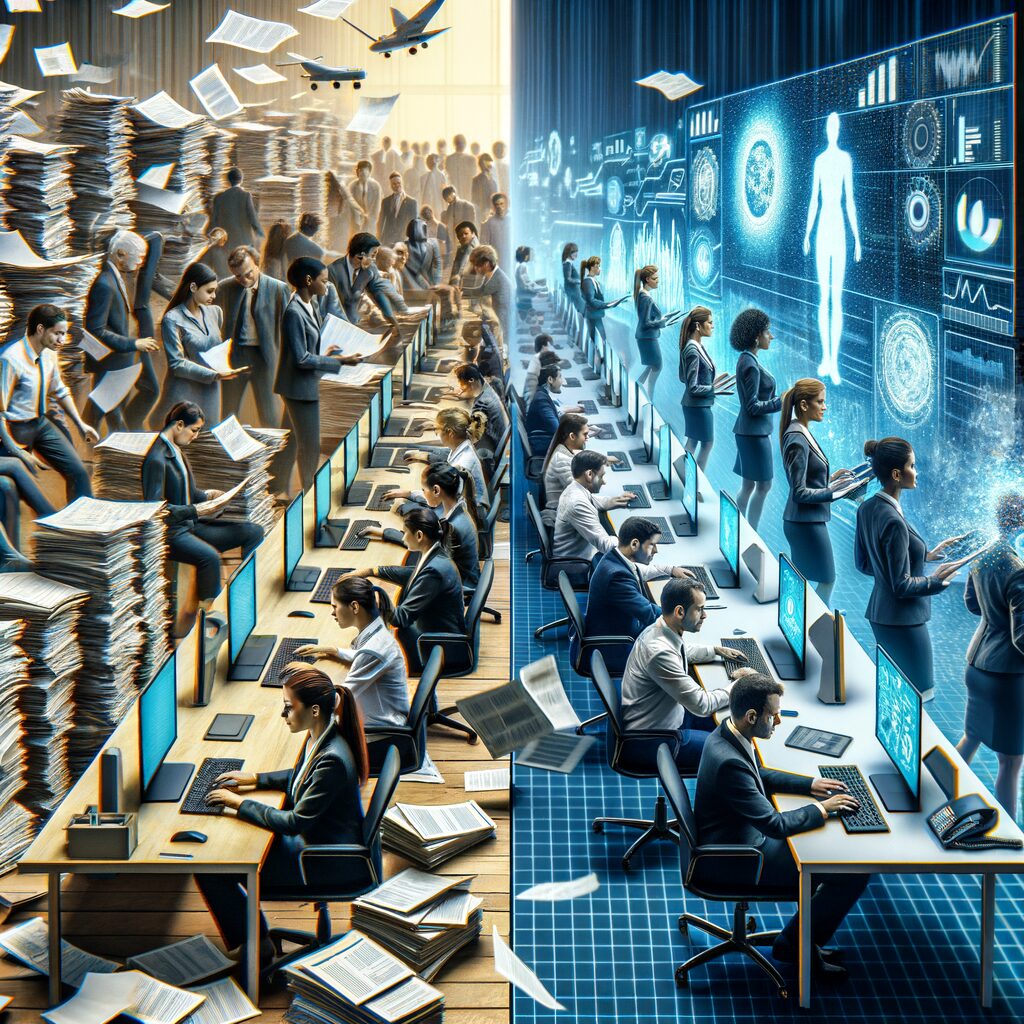

There is a particular kind of exhaustion that lives in procurement teams: the late-afternoon dread when a backlog of requisitions piles up, each one a tangle of PDFs, abbreviations, and vague descriptions. You open an attachment, squint at a terse item description, ping a supplier, wait for a quote. Someone on the team cross-checks an approved vendor list in a spreadsheet that hasn’t been updated in months. The approvals thread winds through inboxes and Slack channels. Days stretch into a week before a PO is finally issued — and often it’s corrected after the fact.

This isn’t just frustration; it’s wasted labor, missed discounts, and invisible risk. The good news is that a pragmatic combination of AI and automation can undo that drag. By applying natural language processing to understand requisitions, machine learning to find the best supplier matches and predict prices, and workflow automation to execute approvals and POs, small and mid-sized businesses can compress the purchase requisition-to-supplier matching cycle from days to hours — and free procurement to do higher-value work.

How the solution fits together — a step-by-step approach

- Start with data preparation

- Inventory: Gather requisitions, POs, supplier catalogs, contract terms, historical invoice and delivery records, and any approval logs. Include both structured fields and the unstructured text in email and attachments.

- Clean and normalize: Standardize units, currencies, part numbers, and vendor names. Tag synonyms and remove duplicates. Quality here is everything — models inherit your data’s errors.

- Label a seed set: Manually label a representative sample of requisitions with the correct supplier match and outcome (accepted quote, reorder, rejected). This small labeled set will guide model training and human-in-the-loop workflows.

- Use NLP to understand requisitions

- Extract intent and entities: Use NLP models (spaCy, Hugging Face transformers, or the NER tools in cloud providers) to pull out product names, specifications, quantities, delivery dates, and budget codes from free text and attachments.

- Map to catalog items: Where part numbers or SKUs exist, tie them to catalog entries; where they don’t, create normalized descriptions and attribute profiles for matching.

- Build a supplier similarity and matching model

- Feature design: Combine textual embeddings of item descriptions (sentence-transformers), categorical attributes (material, brand), historical pricing, lead time, and supplier reliability scores.

- Matching engine: Use vector search libraries (FAISS, Annoy, Milvus) for fast nearest-neighbor lookup against supplier catalog embeddings, and a supervised classifier (scikit-learn, XGBoost, or light neural nets) to score supplier suitability.

- Price prediction: Add a regression model to estimate expected price ranges and flag outliers that need manual review.

- Integrate live catalogs and ERP systems

- Catalog standards: Connect via cXML, OCI, punchout, or supplier APIs to keep pricing and availability live. For suppliers without APIs, set scheduled catalog ingestions.

- ERP/Procurement integration: Use middleware or iPaaS (Workato, MuleSoft, Zapier for simpler flows) to create POs directly in your ERP (NetSuite, SAP Business One, Microsoft Dynamics) once approvals are completed.

- Orchestration: Use workflow engines or RPA (Camunda, Temporal, UiPath, Power Automate) to manage routing, escalations, and exception handling.

- Automate approval thresholds and routing

- Rules engine: Encode business rules — by category, dollar amount, or supplier risk profile — to determine when automated matching can proceed to PO and when human approval is required.

- Dynamic thresholds: Allow the system to escalate lower-value exceptions automatically and send higher-risk items for review. Keep override logs for auditability.

- Create feedback loops for continuous improvement

- Human-in-the-loop: Capture corrections when a buyer changes the matched supplier or edits quantities. Use these as labeled examples to retrain and improve the model.

- Monitoring: Track match accuracy, false positives (wrong supplier matches), and the rate of exceptions. Retrain models periodically and when major catalog or supplier changes occur.

Expected benefits — what to expect (without promises)

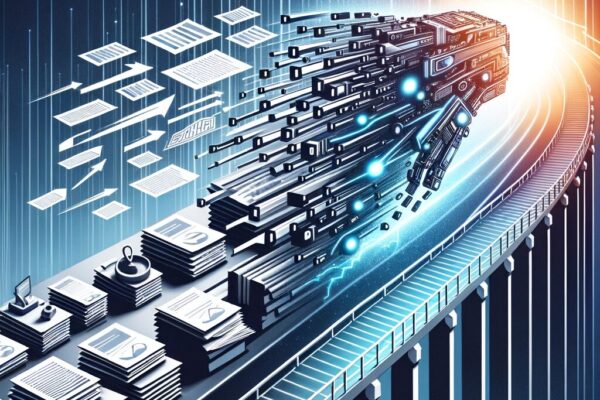

- Cycle compression: The biggest, most visible change is time. Automated extraction and matching can reduce manual handling and move many requisitions from days of back-and-forth to a few hours of automated processing and light review.

- Staff redeployment: Buyers stop acting as data clerks and focus on negotiation, relationship management, and strategic sourcing.

- Fewer errors: Automated matching, validated against live catalogs and historical patterns, reduces mis-POs and the downstream costs of returns and corrections.

- Better compliance: Automated routing enforces approved supplier lists and contract pricing more consistently than manual processes.

Common pitfalls and how to avoid them

- Data bias and supplier favoritism: If historical data reflects preferential treatment of certain suppliers, the model may learn to favor them even when not optimal. Counter this by including fairness checks and business-rule overrides tied to sourcing policies.

- Catalog freshness and supplier resistance: Suppliers may not expose APIs or update catalogs promptly. Solve this by prioritizing strategic suppliers for live integration and using scheduled ingests for the rest.

- Change management: Procurement teams may distrust automated matches at first. Start small with a pilot category, provide transparency into why a match was chosen, and keep human approval in the loop until confidence grows.

- Integration complexity: ERP connectors and legacy systems can be brittle. Work incrementally: build a bi-directional data flow for a single category, validate, then expand.

Practical success metrics to track

- Match accuracy (%) — ratio of automatic matches accepted without change.

- Auto-PO rate — percent of POs created without manual intervention.

- Procurement cycle time — average time from requisition submission to PO issuance.

- Exception volume — number of requisitions sent for manual review.

- Maverick spend (%) — purchases made outside approved channels.

- Cost per requisition — total procurement cost divided by number of requisitions.

Realistic vendor and technology options

- NLP/embeddings: spaCy, Hugging Face transformers, sentence-transformers.

- Vector search/ANN: FAISS, Annoy, Milvus.

- ML frameworks: scikit-learn, XGBoost, TensorFlow, PyTorch.

- Integration and iPaaS: Workato, MuleSoft, Zapier, Make.

- RPA and orchestration: UiPath, Automation Anywhere, Microsoft Power Automate, Camunda.

- ERPs: Oracle NetSuite, SAP Business One, Microsoft Dynamics.

- Supplier data providers: Dun & Bradstreet, native supplier APIs, and catalog standards like cXML/punchout.

Pilot checklist — a practical starting kit

- Choose one high-volume but narrow category (e.g., MRO parts).

- Inventory and clean all related data sources.

- Label a 200–500 item sample with correct supplier matches.

- Build an initial NLP-based extractor and a simple similarity matcher.

- Integrate with ERP for read-only validation, then enable PO creation in a controlled sandbox.

- Define approval thresholds and train your team on the new flow.

- Monitor match rate and error cases for the first 30–90 days and iterate.

If procurement feels like a recurring paper cut, this approach stitches the wound. It’s not black-box magic — it’s a practical assembly of tools and rules that digitize the repetitive parts of your workflow and surface human judgment where it matters.

MyMobileLyfe can help. If your team wants to move from lengthy manual cycles to a streamlined requisition-to-supplier flow, MyMobileLyfe offers hands-on expertise to design, integrate, and operationalize AI, automation, and data solutions that reduce cycle time, improve accuracy, and lower costs. They’ll help you pick the right pilot, avoid common pitfalls, and scale the automation across categories so procurement teams can finally work on the parts of the job that require judgment, not copy-and-paste.

Recent Comments